The Day I Damaged Company Property

By Ron Petrie

Fred Streeter and I signed on at Vauxhall, pass to Waterloo, relieved on number 11 platform, Merchant Navy stopping at Southampton and Bournemouth Central where we were relieved. Sorry I am unable to remember the exact times or indeed the loco number, all I can say is we signed on somewhere between 07.30 and 10.30. As for our load, the back of the tender was level with the running foreman's office. We had a good trip down with nothing untoward happening so we retired to the club for refreshment, liquid of course.

We were standing on the up platform when our loco came in, an unconverted West Country in a filthy state. It looked as if it hadn't been cleaned for years, to our amazement the driver said she's a goodun, again I can't remember the number. After taking water, pushing coal forward, and getting coaches attached we were off, stopping all stations to Brockenhurst, when we left Christchurch and started up the bank I said to Fred she is a goodun, Fred agreed and said the reverser is behaving itself. I had the firehole door on the second notch and that is where it stayed, when I wasn't shoveling.

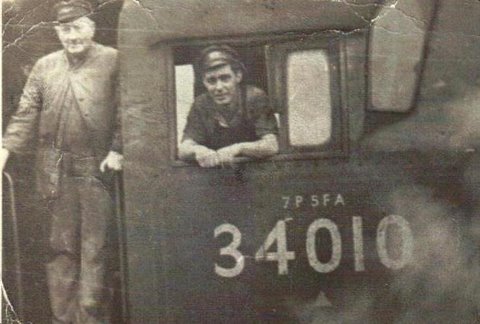

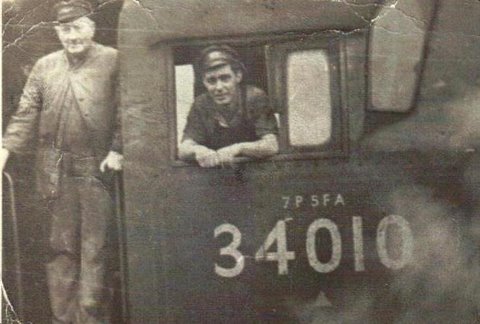

Ron Petrie and Fred Streeter on the up ACE, Salisbury September 1963.

(Photo Ron Petrie collection)

After Brockenhurst I started to fill the box up, when we stopped at Southampton the coal was nearly rolling out the door and we took water. Back on the footplate Fred looked at the fire and said OK, I am the injector boy now and sat on my seat. We left Southampton and through the tunnel I gave her a touch of blower and shut the regulator to slow for the Northam curve, she blows off just as Fred put the injector on. As we eased round the curve I started to give her a bit of regulator and 30% as we passed Mount Pleasant I went over to Fred's side and looked out the door. Fred said what are you doing? I said looking for the St Denys home, I will tell you that, get over your own side, we both laughed Fred had a dry sense of humour. I had in fact seen the signal and had started to open her up when I got a wave from Fred. I said you are too late, again we laughed. I tried reducing the cut off to 15% but she started to see-saw a bit so I settled on 18% ( if you can rely on the indicator ) then again to 25% after Swaythling I then drove on the regulator. We stopped at Eastleigh and Winchester. The firehole door was still on the second notch, boiler pressure on the mark, water top nut, injector cut fine, shut the regulator and it blows off, what more could one ask for? It is said 'don't judge a book by it's cover', and this engine was a typical example of this. Fred started to put coal in the back corners as we passed Winchester Junction ( the Alton line ) I increased cut off to 30% with about 3/4 regulator, after we had gone through Waller Ash tunnel and I had seen the home signal, I looked in the firebox Fred said get over your own side and started to put more coal in the back corners.

As we came off the Quadruple track at Weston Box, Fred put the injector off (after checking the gauge glasses the water was well in the top nut) there was a tremendous roar of steam under the footplate, it was like having the blowdown wide open only worse. We both looked at each other and swaped places, straight away we both realised what it was. I opened the firehole door wide put the other injector on, and I wished for an LNER locomotive (explanation later). We stopped at Micheldever as booked, the platform being on the driver's side the footplate became a Turkish bath, we both got down onto the platform, I took the coal pick with me, the whole cab was engulfed in steam. I climbed up the ladder on the back of the tender along the side on to the engulfed cab roof and along the top of the boiler to find the 2 foot square (approx.) thin metal plate in position with all of its bolts 16 to 20 3/8 bolts. I had to make a decision, are we to be a complete failure? If I drop the fire it would burn the track and probably the loco as well, if I had a spanner I would of had to lay across the boiler top and undo every bolt, and that would take forever. I did not hesitate, I swung the coal pick pointed end at the plate. I was tearing the plate away from the bolts. I kept on until I got to the front clack valve I gave it a wallop, wrong one, more bashing ensued until I could get to the back one, the plate was about 3/4 off from the front when I gave the back clack valve a thump and down it went, then all was peace and tranquility. When the steam cleared I was being applauded by Fred, the guard, station staff and about a dozen passengers on the platform.

Back on the footplate we have 1/4 glass water 160 lbs steam the injector is still on, I put more coal in the back corner's and shut the door. I opened the water valve more and blower is full on, she is making steam, I said to Fred I am not going to chance using that injector again, he agreed. We left with 1/2 glass water and 170 lbs steam

passing Wooton Box we had about less than 1/4 glass and just under 200 lbs steam I opened the injector water valve more and Fred eased up with the regulator. I said

to Fred we will take water at Basingstoke we have used a lot, but don't brake too hard at Basing. We ran in gently I put the pipe in we had used over 1/2 tank of water,

after looking at the plate hanging on the top of the loco, Fred attended to my fire. We left next stop Woking by the time we got to Winchfield we were practically back to

normal, Fred had come over to my side looked at the plate hanging and refered to it as looking like a certain Nine Elms driver's right ear. When we went through the

aqueduct just after Sturt Lane we both stood in the middle of the cab.

We stopped at Woking and a railway inspector came to the loco to inform us that we had a lump of metal hanging from the top of the loco, as if we didn't know. When we ran into Waterloo platform 15 Phil Jarman, the running foreman, was standing on the end of 14 by the buffer stops. He walked round, our relief were there, there were six people all talking at once, and the Guard giving Fred the obligatory lost time ticket. I got back on the loco and explained to the fireman what had happened. I said to him to see the running foreman when you get back, you will probably have to drop the fire for the fitter's to look at the clack, don't use the injector and it's the one with the pet pipe. When I got onto the platform Phil Jarman said to me that I would be reported for damaging company property after what I had gone through. I just exploded, wrong thing to say at the wrong time, he took one look at me and ran, Fred was at the same time trying to reasure me that he was only winding me up. The next day Fred and I were up and down between Waterloo and Clapham with empty stock, I did all the driving, we had pushed out of 11 and Phil Jarman came up and apologised to me and said I should not have said that, we shook hands and that was it as far as I was concerned.

About a fortnight later I was called to the shedmaster's office. Vic Gilchrist (Nine Elms Shedmaster) and Stan Downs (Motive Power Superindendent) were there. Vic said Fred had written a detailed report on what had happened and what I had done about it. I said did I have an alternative to what I did? I went on to say that I blamed Mr O.V.S Bulleid for putting the clack valves or to be precise injector boilerwater non return valves, under a bit of tin in an inaccessible place. Even on the converted engines on the run you would have to stop to get to the clacks. I stated that I had got a Q1, a Charlie, ready at Guildford Loco and the clack stuck open. The fitters were called (John Daily and Ernie Pitman), it took them about 10 minutes to get the plate off, that's after they had found a ladder. We had to have another engine.

I said that Bulleid had started at Doncaster works in 1901 which was the Great Northern Railway until 1923 when it became the London North Eastern Railway, he was

to become assistant to Sir Nigel Gresley, Chief Mechanical Engineer, before coming to the Southern in 1937. He had not learned anything, where were all the clack valves on LNER locos - on the boiler front. It is the same casting as the injector live steam valve, one each side of the gauge glasses. Vic Gilchrist knew what I was saying as he was from up that way, he wanted to know how I knew. I said I had travelled between King's X and Arbroath many times and not always on the cushions. They both laughed. Vic started to mention some names, I confirmed yes I knew some of them. But that's another story. They both thanked me and said that I had done the best I could and prevented a complete failure. We shook hands and went our own ways. Fred never did tell me exactly what he wrote in his report. Every time I see Phil Jarman he grins and calls me Ron. Happy Days.

After thought: I did say at the meeting with Vic Gilchrist and Stan Downs that I thought it would be a good idea to have hinges lugs hooks fitted to the metal plates, anything that

would make it easier to get to the clacks. They both agreed and said it would be looked into. As it turned out these plates became discarded on an as and when basis. This could be a lesson for preservationists who own unconverted Bulleids. Only fit plates that are easy to remove, and take a ladder with you!

Regards Ron Petrie.

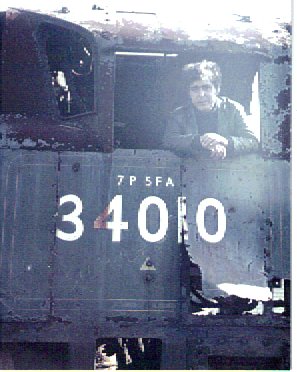

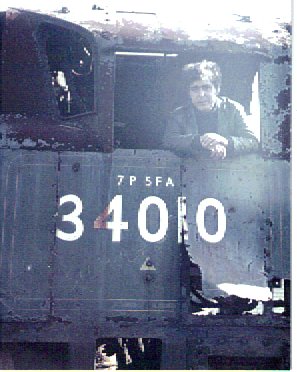

Ron Petrie reunited with 34010 at Woodham's scrapyard Barry South Wales August 1976.

(Photo Ron Petrie collection)

Copyright 2009 © Ron Petrie